Usually sold by the cubic yard, concrete is a mix of sand, gravel, and cement. However, pre-mixed concrete is also available. Since you often only get one attempt at pouring, you need to estimate the material amount as accurately as possible. Make sure that the installation team is ready to begin the installation as soon as the truck arrives so that the installation can begin without wasting time setting up the truck.

Workflow

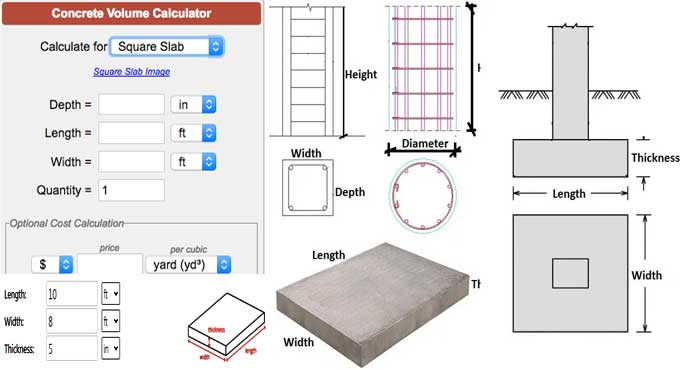

The slab, footing, or column should measure for length, width, and height. Calculate the concrete needed for each pour if the area is complex or multiple pours are required. To measure slabs that are not simple rectangles, you might want to break them into separate sections and measure each separately.

1. If they haven’t already converted to feet, do so. Converting inches, yards, or meters to feet is easy with conversion calculators. You multiply the width times the length times the height (W * L * H) to figure out how many cubic feet there are.

2. From cubic feet, multiply the volume by cubic yards. Calculate how many yards of concrete you need by dividing the cubic footage by 27.

3. If you can’t find a supplier that sells fractions of a yard, round up to the nearest yard. You should ask your supplier if they will sell a partial yard of material, but most don’t.

4. When ordering concrete for smaller projects, estimate how many bags of premixed concrete you will need.

5. There is a comparison of the coverage of various premix bags. The average cubic yard of concrete can be filled with 90 forty-pound bags, 60 sixty-pound bags, or 45 eighty-pound bags.

Published By

Arka Roy

www.constructioncost.co